About Us

Shree Chamunda Group Of Industries

Three Units, area, facility, etc.

SHREE CHAMUNDA GROUP OF INDUSTRIES is an FLANGES MANUFACTURER company established in 2001 by a team of Qualified Engineering and Management Professionals, our company has been successfully serving the process and engineering industry for the past decades. We are specialized in ALL TYPES OF FLANGES INCLUDE THE variety of metals like MS and SS etc.

- As a experianced fabricator , we are giving services to our clients from large variey of verticals described in core market sector. We have land of about 25000 sq.ft on which 20000 manufacturing constructed fabrication workshop backed by 95HP Power load sanction and 100% generator backup.We have latest machinery and infrastructure to cater the requirement of our reputed clients. We have large number of skilled workers who are given timely training in there skill areas.

- We have excellent infrastructure facilities under one roof and are backed by fine resources of different capacity hydraulic press machines, heavy capacity plate bending machine along with various other conventional fabrication, machining and lining equipments.

We also serve large and small scale engineering organizations as sub-contractor for their requirement of FLANGES FORMING AND ALLIED MANUFACTURING OPERATION.

Our Company is ISO 9001-2015/Cer.No:106073/A/0001 certified and believe in maitaining quality standards for all in house process and procedures. We are ensuring that the customer always get the best in quality and service. This is our philosophy that enables us to look forward to the future with confidence. The company’s major strength has always been its committed and dedicated team of managers, staff and technicians. This factor, coupled with a sound engineering base and an excellent reputation for service, quality, reliability and integrity, has transformed the organization from a single product to multi-product company providing services to a wide range of industry.

Serving Sectors:

- Steel

- Cement

- Paper & Pulp

- Cold Storage

- Automobiles

- Breweries

- Transportation

- Food & Dairy

- Waste Management

- Paint

- Heavy Engineering

- Oil & Gas

- Power Generation

- Textile

- Petrochemicals

- Sugar

- Environ Protection

- Rubber

- Pollution Control

- Fertilizers

Infrastructure:

CNC

DX-200 Model

Capacity up to 330mm OD

15 Machine

VMC

VMC-430 Model

Capacity up to 300mm OD

2 Machine

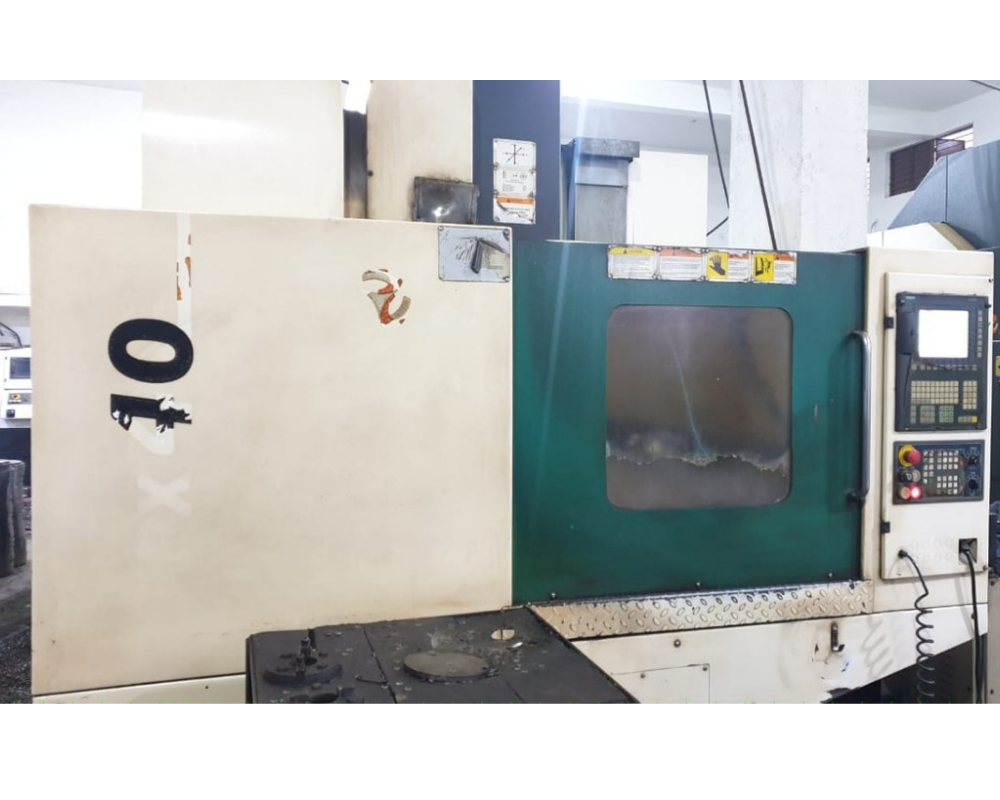

VMC

SX4 Model

Capacity up to 300mm OD

1 Machine

VMC

PX-40

Capacity up to 400mm OD

1 Machine

VMC

PX-20 Model

Capacity up to 380mm OD

1 Machine

LATHE MACHINE

For continuous light & heavy duty jobs and to give prolonged efficient life. Lathes machine are made in simple & 3-speed gear box types & possess exceedingly improved features both in construction & design.

PROFILE CUTTING MACHINE

Profile Cutting Machine is a heavy duty foundation mountable cutting machine, it can be used for large duplication type jobs particularly large production untiring multiple shift production application. This is simplest and one of the most accurate magnetic tracing system, which helps in maintaining repeatability of the flame cut parts. It saves production time, material, wastage as well as finishing operations of components. Fully complete basic raw materials like : Rings, Stripes, Hooks, Gussets, Ribs, Supports, Circles, Blanks, Tops and Bottoms, Side Plates of odd profile shapes of thickness ranging from 150 mm in mild steel are available.

DRILL MACHINE

- Quality of drilling, as well as strength and durability.

- This machines are widely used to deliver stable performance during drilling process.

- Flawless operations for longer hours due to the drilling heads with longest possible radius from the columns.

- used in woodworking, metalworking and construction applications

HYDRAULIC PRESS ( STERLING PRESS)

Used after profile cutting, this facility has a capacity equal to a 250 ton hydraulic press. Results in minimum machining allowance and saving of raw material. Used after profile cutting, this facility has a capacity equal to a 250 ton hydraulic press. Results in minimum machining allowance and saving of raw material.